In the ever-evolving world of additive manufacturing, achieving consistent, high-quality prints and expanding your material palette are often top priorities. If you’ve been navigating the complexities of 3D printing, especially with advanced filaments, you’ve likely encountered challenges that an Enclosed 3d Printer can effortlessly resolve. This isn’t just about adding a box around your machine; it’s about transforming your printing capabilities, ensuring safety, and elevating your results to a professional standard.

For over 15 years, I’ve seen firsthand how the right equipment can make all the difference. An enclosed 3D printer addresses many of the environmental variables that can plague even the most experienced makers, paving the way for a more reliable, versatile, and enjoyable printing journey.

What Exactly is an Enclosed 3D Printer?

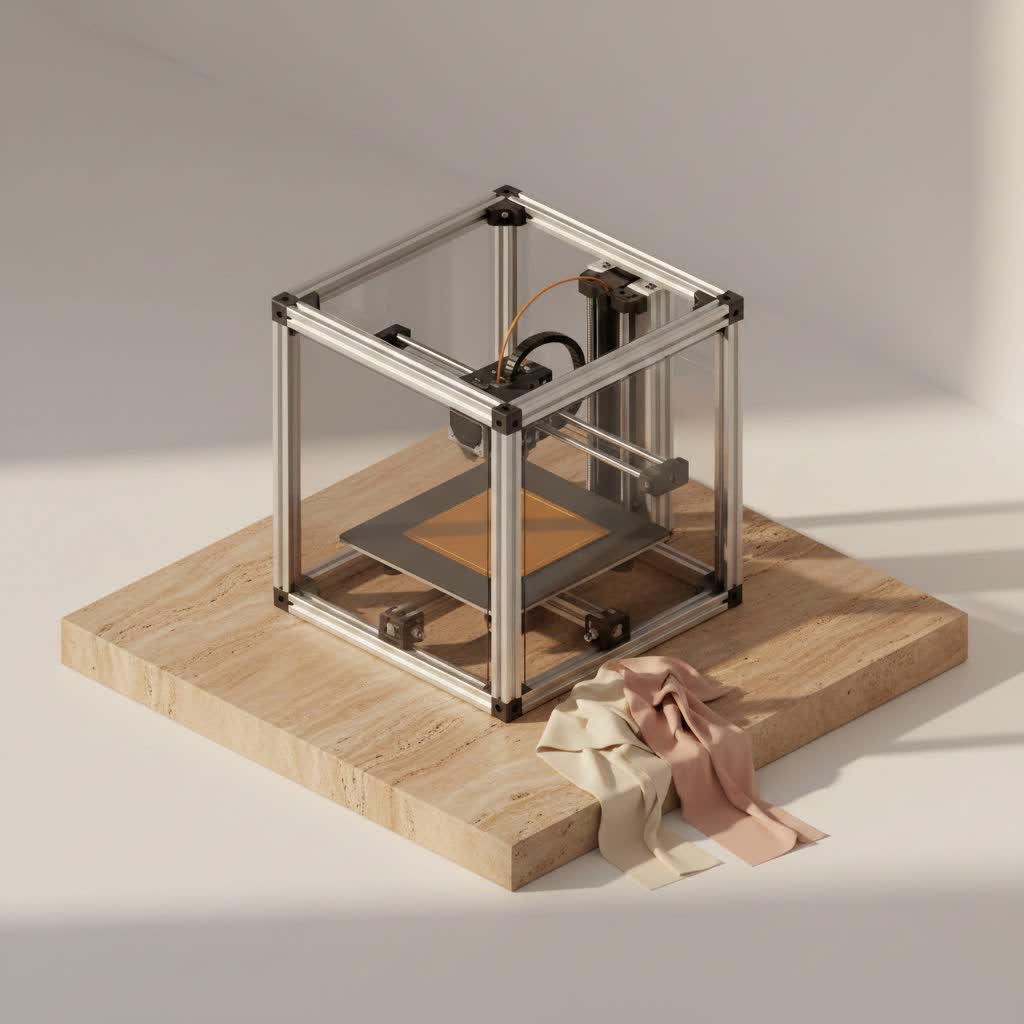

At its core, an enclosed 3D printer is simply a 3D printer where the entire build volume is housed within a protective case or cabinet. Think of it as a mini-environment specifically designed for your printing process. This enclosure often features clear doors or panels, allowing you to monitor your print without compromising the internal conditions. The primary function of this design is to create and maintain a stable, controlled atmosphere around your printing area, shielding your work from external influences like drafts, dust, and temperature fluctuations.

The Unbeatable Advantages of Enclosed 3D Printers

The benefits of utilizing an enclosed 3D printer extend far beyond mere protection, fundamentally enhancing the printing process and the quality of your final products.

Mastering Temperature-Sensitive Materials: Say Goodbye to Warping

One of the most significant advantages of an enclosed 3D printer is its ability to handle temperature-sensitive filaments with remarkable success. Materials like ABS, ASA, Nylon, Polycarbonate, and various carbon fiber-filled composites are notoriously difficult to print on open-frame machines. Why? Because as these engineering-grade filaments cool too quickly or unevenly, they tend to shrink, leading to frustrating issues such as warping (where corners lift off the build plate) and layer separation.

An enclosure traps the heat generated by the print bed and hot end, maintaining a consistently warm internal chamber. This stable thermal environment ensures that the filament cools gradually and uniformly, dramatically reducing internal stresses and virtually eliminating warping and delamination. It’s like giving your print a cozy, controlled cocoon, allowing it to solidify perfectly.

Superior Print Quality and Unwavering Reliability

Beyond preventing common failures, an enclosed environment actively contributes to higher overall print quality and reliability. By removing external variables like sudden drafts or ambient temperature swings, the printer can operate under more consistent conditions. This stability translates directly into:

- Stronger Layer Adhesion: Consistent temperatures help each new layer bond more effectively to the previous one, resulting in stronger, more durable parts.

- Improved Dimensional Accuracy: Parts maintain their intended dimensions more precisely, which is crucial for functional prototypes and components that need to fit together perfectly.

- Smoother Surfaces and Sharper Details: Without environmental interference, corners print sharper, edges are cleaner, and surfaces exhibit fewer visible lines or imperfections.

- Fewer Failed Prints: Ultimately, a controlled environment means less troubleshooting and fewer wasted materials, boosting your productivity and confidence.

A Safer and Quieter Printing Experience

Safety and comfort in your workspace are paramount, and an enclosed 3D printer significantly improves both.

- Fume Containment and Filtration: Many advanced filaments, particularly ABS and some resins, can release volatile organic compounds (VOCs) and ultrafine particles during printing. An enclosure contains these emissions, and when paired with an activated carbon or HEPA filtration system, it actively scrubs the air, preventing harmful fumes from spreading throughout your home or workshop. This is a non-negotiable for health and safety.

- Protection from Hot Parts and Moving Components: 3D printers operate with heated components (nozzles reaching over 200°C, print beds over 100°C) and rapidly moving parts. An enclosure acts as a physical barrier, safeguarding curious hands (especially children) and pets from accidental contact, thereby creating a much safer operating environment.

- Noise Reduction: The whirring of stepper motors and cooling fans can be surprisingly loud, especially during long print jobs. The physical walls of an enclosure act as an effective sound dampener, significantly reducing operational noise. This makes enclosed printers far more suitable for home offices, classrooms, or shared workspaces.

Protecting Your Investment: Dust, Moisture, and Longevity

Your 3D printer is an investment, and an enclosure helps protect it, ensuring a longer, more efficient lifespan.

- Keeping Dust Out: Dust and airborne debris are enemies of precision machinery. They can accumulate on lead screws, guide rails, and even enter the hot end, leading to clogs, reduced print quality, and increased maintenance. An enclosure acts as a shield, keeping these contaminants at bay.

- Moisture Control for Filament: Many filaments, especially Nylon and PETG, are hygroscopic, meaning they absorb moisture from the air, which can lead to bubbling, stringing, and weakened prints. While not a complete solution, an enclosure provides a more stable, less humid environment for your filament during printing, especially when combined with desiccants.

- Extending Printer Lifespan: By protecting internal components from environmental wear and tear, and by operating under more stable thermal conditions, an enclosed 3D printer can enjoy a longer, more trouble-free operational life.

Enclosed vs. Open-Frame: Making the Right Choice

The choice between an enclosed and an open-frame 3D printer boils down to your specific needs, budget, and the materials you intend to print.

Open-frame printers are typically more affordable, offer easier access for maintenance, and are highly customizable. They excel with beginner-friendly filaments like PLA and TPU, which often benefit from rapid cooling. If you’re primarily printing these materials in a stable, draft-free environment, an open-frame model can be an excellent entry point.

However, an enclosed 3D printer becomes essential when you:

- Plan to work with engineering-grade filaments (ABS, ASA, Nylon, PC, composites).

- Prioritize consistent, high-quality, and reliable prints with minimal failures.

- Are concerned about safety from hot parts, moving components, or airborne emissions.

- Need to reduce noise in your printing environment.

While it’s technically possible to print some temperature-sensitive materials on an open-frame printer in a perfectly controlled room, it’s often a frustrating and unreliable endeavor that leads to significant material waste. An enclosure provides the necessary environmental control to succeed consistently.

Navigating the Downsides: What to Consider

While the advantages are compelling, it’s important to be aware of potential considerations when opting for an enclosed 3D printer.

The Initial Investment: Is It Worth It?

Enclosed 3D printers often come with a higher upfront cost compared to their open-frame counterparts. The additional materials, integrated safety features, and sophisticated temperature management systems contribute to this. However, many makers find this investment pays for itself quickly through reduced material waste from failed prints, expanded material capabilities, and the sheer reliability and quality of the output. It’s an investment in functionality and peace of mind.

Accessibility and Maintenance

With a protective enclosure, accessing internal components for routine maintenance, troubleshooting, or even simply removing a finished print can be slightly more cumbersome than with an open-frame design. However, well-designed enclosed printers feature intelligent door and panel placements to mitigate this, offering good access when needed.

PLA and Enclosures: A Delicate Balance

Interestingly, the very feature that makes enclosed printers excel with advanced materials can sometimes be a minor drawback for PLA. PLA typically prints best with good cooling. In a heated enclosure, excessive heat can sometimes lead to issues like “heat creep” (where the filament softens too high up in the hot end, causing clogs) or stringing. However, most modern enclosed printers offer chamber temperature control or excellent ventilation options, allowing you to manage the environment effectively even when printing PLA.

DIY Enclosures: A Budget-Friendly Path (with Caveats)

If a pre-built enclosed 3D printer isn’t in your immediate budget, constructing a DIY enclosure can be a viable and rewarding project. Many makers repurpose IKEA furniture or build custom boxes from materials like acrylic sheets, wood, or aluminum extrusions.

While a DIY enclosure offers cost savings and complete customization, it’s crucial to prioritize safety and functionality:

- Material Choice: Use fire-retardant materials. Cardboard boxes, while tempting, pose a significant fire hazard due to the high temperatures generated by 3D printers. Polycarbonate or flame-retardant composites are safer choices.

- Ventilation and Filtration: Ensure adequate ventilation to prevent heat buildup and, critically, integrate a robust filtration system if you plan to print fuming materials. Concentrated pollutants in an unventilated enclosure can be highly toxic.

- Access and Monitoring: Design doors for easy access and include transparent panels for clear monitoring of the printing process.

Expert Insight: The WMTSV Perspective

“From my early days in 3D printing, battling warped ABS prints and dealing with lingering odors, the evolution towards enclosed systems has been transformative,” notes Dr. Anya Sharma, a leading materials scientist and long-time contributor to WMTSV.com. “Modern enclosed 3D printers aren’t just about containment; they’re integrated systems designed for material optimization, environmental control, and user safety. They represent a fundamental shift towards making industrial-grade results accessible to every maker.”

Conclusion

Choosing an enclosed 3D printer is more than just an upgrade; it’s an investment in expanding your creative possibilities, ensuring the reliability of your prints, and providing a safer, more pleasant environment for your passion. While the initial cost might be a consideration, the long-term benefits in material versatility, print quality, and peace of mind are invaluable. As you continue your journey in 3D printing, embracing an enclosed system will empower you to tackle complex projects with confidence, push the boundaries of material science, and consistently achieve professional-grade results. What advanced project will you embark on next with the newfound capabilities of an enclosed 3D printer? Share your experiences and insights with the WMTSV community!