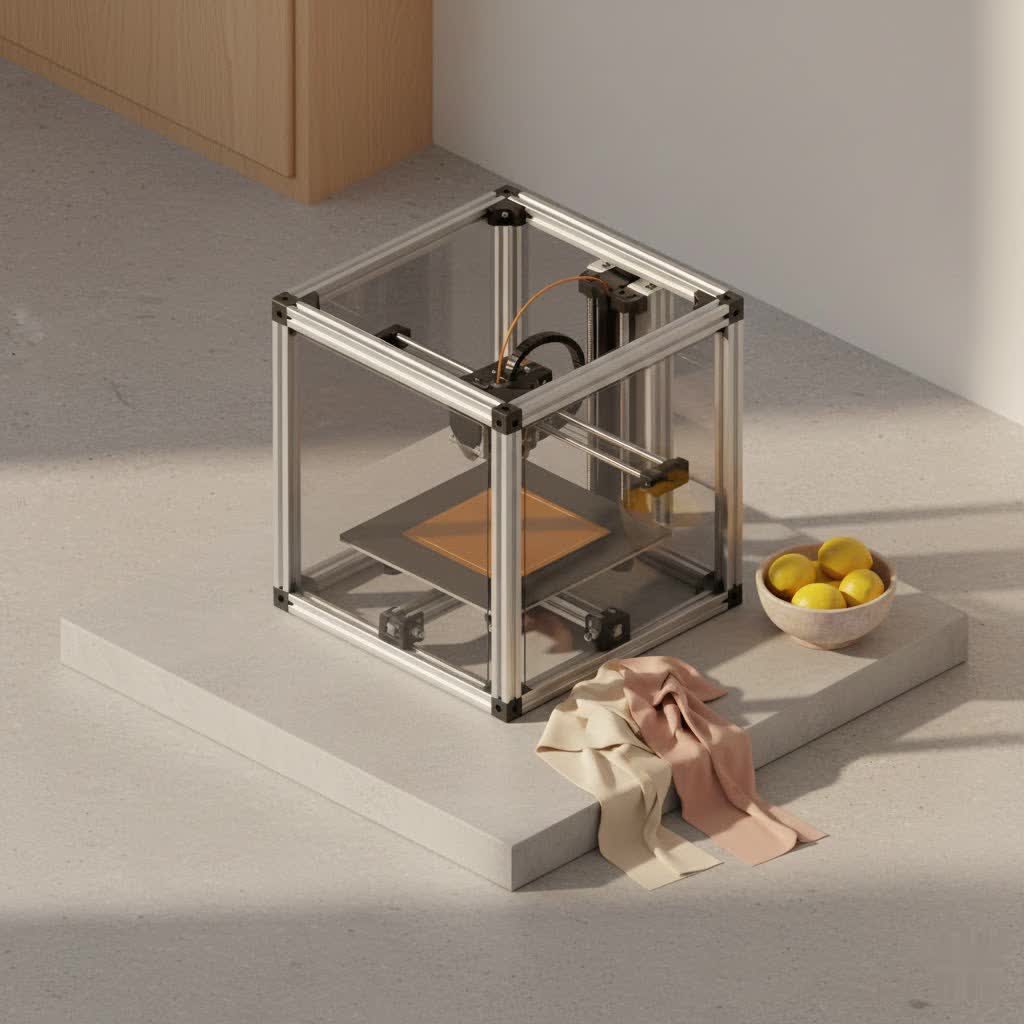

Remember when 3D printing was all about monochrome objects? Those days are rapidly becoming a colorful memory! Today, Color 3d Printers are transforming how we design, prototype, and create, moving beyond simple single-color prints to bring vibrant, lifelike models into existence. This isn’t just a fancy add-on; it’s a game-changer for industries and hobbyists alike, opening up a universe of creative possibilities. At WMTSV, we’ve seen this evolution firsthand, and we’re here to guide you through the dazzling world of printing in every shade imaginable.

What Exactly is a Color 3D Printer?

Before we dive deep, let’s clarify what we mean by a “color 3D printer,” as the term can encompass a few different technologies. Essentially, it’s any 3D printer capable of producing objects with more than one color in a single print. However, there’s a crucial distinction between “multi-color” and “full-color” that’s important to understand.

Multi-Color vs. Full-Color: Understanding the Nuance

When we talk about multi-color 3D printing, we’re typically referring to systems that use multiple pre-colored materials, like different spools of filament or vats of resin. Think of it like swapping crayons during a drawing – you get distinct colors side-by-side. Fused Deposition Modeling (FDM) printers often achieve this through dual extruders, or sophisticated multi-material units (MMU) like those from Prusa, or Automatic Material Systems (AMS) from Bambu Lab. Some simpler methods involve pausing a print to manually swap filaments. These systems offer distinct color blocks and excellent material variety.

Full-color 3D printing, on the other hand, is a whole different beast. Imagine an inkjet printer, but instead of paper, it’s building a 3D object, mixing CMYK (Cyan, Magenta, Yellow, Black) inks or binders on the fly to produce thousands, even millions, of reproducible colors and gradients, much like a 2D photograph. These advanced systems can create photorealistic parts, often with intricate textures and precise color matching, including Pantone colors. The difference is akin to choosing from a limited box of crayons versus having a digital color palette with endless shades.

How Does the Magic Happen? Key Technologies Explained

The ability to print in color isn’t a one-size-fits-all solution; it’s achieved through several fascinating technologies, each with its own strengths and ideal applications.

Fused Deposition Modeling (FDM) with Multi-Material Systems

FDM is perhaps the most common and accessible 3D printing technology, and innovations have brought multi-color capabilities to the desktop. Instead of a single hotend extruding one filament, these machines employ clever mechanisms to switch between multiple spools of pre-colored filament during a print.

Systems like Bambu Lab’s AMS or Prusa’s MMU (Multi Material Unit) automatically feed different colored filaments into the print head as needed. Some printers also feature Independent Dual Extruders (IDEX), allowing two print heads to work simultaneously with different colors or materials. While these methods offer incredible creative freedom for a relatively affordable price point, they typically produce parts with distinct color changes, and the process often involves “purge towers” or “poop chutes” to ensure clean color transitions, which can lead to material waste. Despite this, the accessibility and tangible results make them incredibly popular.

Binder Jetting: Powder, Ink, and Vibrant Hues

Moving into the realm of true full-color printing, Binder Jetting technology works quite differently. Imagine a bed of fine powder, often gypsum or a sandstone-like composite. A print head, similar to an inkjet, moves across this bed, selectively depositing a liquid binding agent along with CMYK colored inks. Each layer of powder is bonded and colored, then a new layer of powder is spread, and the process repeats until the object is complete.

The beauty of binder jetting is its ability to create complex geometries without needing support structures, as the unprinted powder acts as its own support. The resulting parts can boast an impressive range of vibrant, full-spectrum colors. However, these prints are often quite fragile in their raw state and require post-processing, such as infiltration with resin or glue, to achieve sufficient strength and durability.

Material Jetting (PolyJet/ColorJet Printing): Precision and Realism

If photorealistic detail and intricate color gradients are your goal, Material Jetting, including technologies like PolyJet (Stratasys) and ColorJet Printing (Mimaki, 3D Systems), is where it’s at. These high-end systems operate by jetting microscopic droplets of liquid photopolymer resin, often in CMYK plus white and clear, onto a build platform. These droplets are then immediately cured by UV light, layer by layer, solidifying the material and locking in the color.

Material Jetting printers can achieve astonishingly fine details, smooth surface finishes, and incredibly accurate color reproduction, even matching specific Pantone shades. They can also create parts with varying material properties within a single print, including clear or rubber-like sections, adding another layer of complexity and functionality. The trade-off? These machines represent a significant investment, making them primarily the domain of industrial applications, specialized service bureaus, and high-end design studios.

Applications: Where Color 3D Printing Shines Brightest

The transformative power of color 3D printing extends across numerous industries, enabling innovations that were once impossible or prohibitively expensive.

Prototyping and Product Design

For engineers and product designers, a “looks-like” prototype is invaluable. Color 3D printing allows them to create prototypes that not only have the correct form and fit but also the accurate color, texture, and branding of the final product. This significantly accelerates design iterations, reduces development costs, and facilitates clearer communication with clients and stakeholders. Imagine presenting a new smartphone design with its actual color scheme or a consumer electronics device with precise branding – it makes a world of difference in securing approvals.

Medical and Educational Models

In healthcare, color 3D printing creates highly detailed and realistic anatomical models. Surgeons use these to plan complex procedures with greater precision, practicing on patient-specific replicas that highlight different tissues and pathologies in distinct colors. Medical students benefit from vibrant, color-coded models that simplify understanding intricate biological structures. Similarly, educators and researchers across various fields leverage multi-color models as powerful visual aids to enhance learning and demonstrate complex concepts.

Art, Figurines, and Entertainment

The artistic community has embraced color 3D printing wholeheartedly. From intricate sculptures and custom jewelry to vibrant character figurines and movie props, the technology offers unparalleled creative freedom. Artists can translate digital designs with complex color patterns and textures directly into physical objects, opening new avenues for expression. This also includes creating lifelike 3D portraits and collectibles, where every nuance of a character or person can be accurately replicated.

Architecture and Industrial Design

Architects can produce highly detailed, visually appealing models of buildings and landscapes, complete with realistic material textures and color palettes. This helps clients visualize projects more effectively and aids in urban planning. In industrial design, color-coded functional parts can be created, improving assembly instructions or highlighting specific features in complex machinery.

Navigating the Challenges: What to Consider

While color 3D printing is a marvel, it’s not without its considerations. Understanding these challenges will help you make informed decisions.

Cost Implications

The most significant hurdle for many is the cost. While multi-color FDM printers have become increasingly affordable (often in the several hundred to a couple thousand dollars range), true full-color industrial machines can easily run into tens or hundreds of thousands of dollars. Beyond the initial investment, material costs can also be higher, especially for specialized resins and binders. Additionally, multi-material FDM systems generate material waste during color swaps, which can add up over time.

Material Limitations and Print Quality

Full-color prints, particularly those produced via binder jetting, can sometimes be more fragile than their monochrome counterparts and may require additional post-processing like infiltration to improve their mechanical properties. Material Jetting produces excellent visual quality but often with parts that are more brittle or heat-sensitive. FDM multi-color prints, while robust, will still exhibit visible layer lines and offer a more limited, discrete color palette compared to the seamless gradients of full-color systems. Color accuracy and consistency can also vary between technologies and even machines.

Workflow and Post-Processing

Preparing files for color 3D printing requires specialized software. Slicing programs like Bambu Studio, PrusaSlicer, or even advanced tools like Adobe Substance, Blender, and Zbrush, allow users to “paint” their 3D models and assign colors to different regions or layers. File formats like 3MF are increasingly important as they can store color and texture information, unlike older STL files. Depending on the technology, post-processing steps, such as removing unbound powder or curing resin, might be necessary.

Choosing Your Palette: Popular Color 3D Printer Models

The market for color 3D printers is dynamic, with innovations continuously making the technology more accessible.

Accessible Multi-Color FDM Systems

For enthusiasts and small businesses, several FDM printers offer excellent multi-color capabilities. The Bambu Lab A1 Mini Combo, P1S, and X1-Carbon series, particularly when paired with their Automatic Material System (AMS), have revolutionized multi-color FDM by making filament changes almost seamless and user-friendly. Similarly, the Prusa MK4 with an MMU3 upgrade provides reliable five-color printing for a loyal user base. The Anycubic Kobra 3 Combo, with its ACE Pro system, is also a strong contender, offering multi-filament printing at a competitive price point. These systems are fantastic for creating functional parts, artistic models, and prototypes with distinct color separation.

Industrial Full-Color Powerhouses

When it comes to true full-color, industrial machines lead the way. Manufacturers like Mimaki (e.g., 3DUJ series), Stratasys (e.g., J-Series with PolyJet technology), and 3D Systems (e.g., ProJet CJP 660Pro with ColorJet Printing) are at the forefront. These printers are capable of producing highly detailed, photorealistic models with an expansive color gamut, making them indispensable for professional applications requiring the utmost visual fidelity. “The leap from monochrome to multi-color, and especially to full-color 3D printing, isn’t just about aesthetics; it’s about unlocking entirely new dimensions of functionality and communication in design and engineering,” says Dr. Evelyn Reed, a renowned materials science expert and 3D printing innovator. “Imagine a surgeon practicing a complex procedure on a fully color-coded, realistic anatomical model, or an architect presenting a scale model that captures every hue of a proposed building. That’s the real impact.”

Conclusion

Color 3D printing has evolved from a niche capability to a powerful tool that’s transforming how we visualize and interact with the physical world. Whether you’re exploring the accessible multi-color FDM systems for hobby projects and functional prototypes, or delving into the professional full-color technologies for photorealistic models, the ability to add vibrant hues to your 3D prints is a game-changer. It’s about bringing your digital ideas to life with unprecedented realism and expressive power.

As this technology continues to advance, we at WMTSV are excited to see the incredible innovations it will inspire. So, what colorful creation will you print next? Dive in, experiment with your palette, and share your vibrant 3D printing experiences with the WMTSV community!