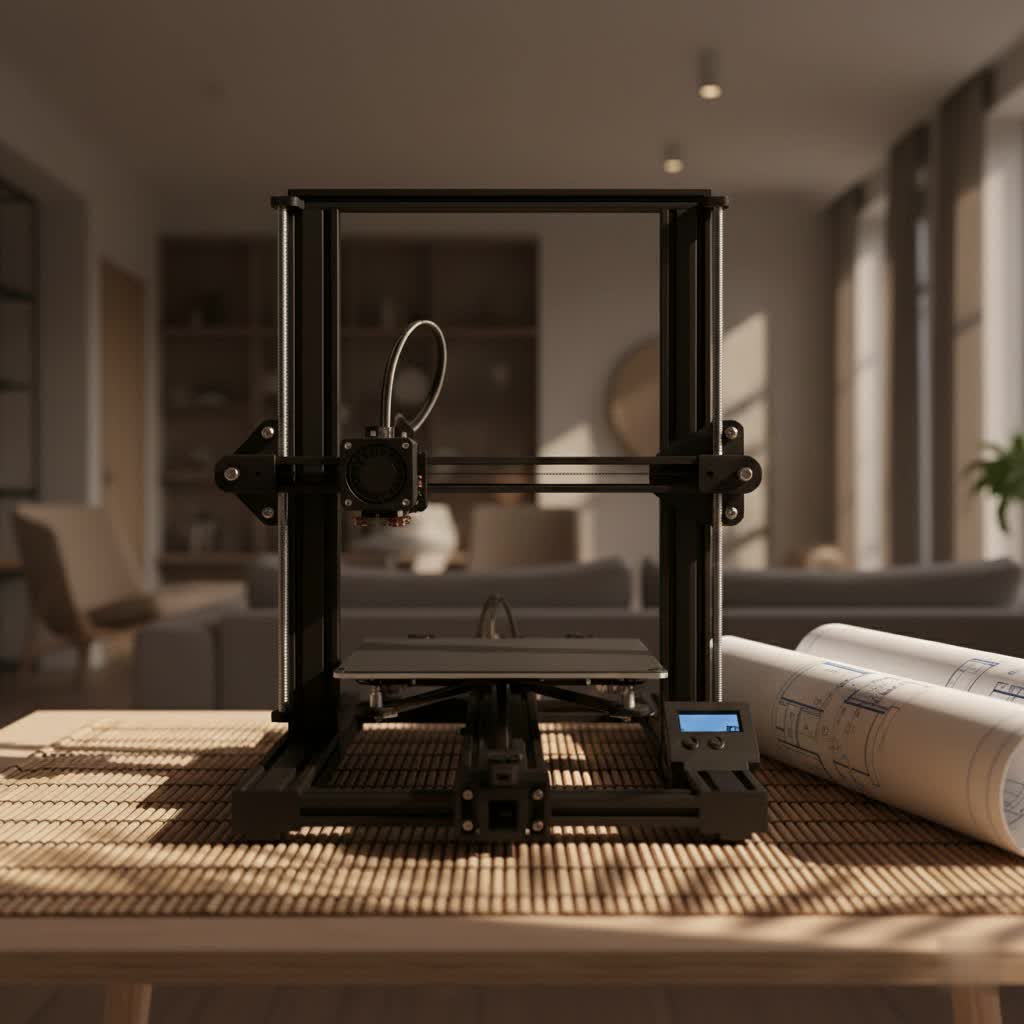

Have you ever imagined creating complex objects right from your desktop, turning digital designs into tangible realities with a flick of a switch? That’s the magic of 3d Printer Printing, a revolutionary technology that’s reshaping industries and sparking innovation worldwide. Here at WMTSV, with over 15 years of hands-on experience, we’ve seen 3D printing evolve from a niche concept to a powerhouse of modern manufacturing, and we’re here to demystify it for you. This isn’t just about printing plastic trinkets; it’s about a fundamental shift in how we design, produce, and imagine.

What Exactly is 3D Printer Printing?

At its core, 3D printer printing, often called additive manufacturing, is a process of making three-dimensional solid objects from a digital file. Instead of carving away material from a larger block, like a sculptor chipping away at marble (that’s “subtractive manufacturing”), 3D printing builds an object layer by meticulous layer. Think of it like constructing a multi-layered cake: you start with a base, then add successive layers until your confectionery masterpiece is complete. Each layer is a thinly sliced cross-section of the final object, fused together to form a coherent whole. This additive approach minimizes waste and opens up a world of possibilities for intricate designs that were once impossible to create.

The Journey from Idea to Object: How 3D Printer Printing Works

The process of bringing a digital concept to a physical object through 3D printer printing is a fascinating blend of art and engineering.

Designing Your Digital Masterpiece (Modeling)

Every 3D print begins with a digital blueprint, a 3D model. You can either design this model from scratch using Computer-Aided Design (CAD) software, or if you’re feeling adventurous, scan a real-world object with a 3D scanner to create its digital twin. Popular file formats for these models include STL (Stereolithography) and the more advanced AMF (Additive Manufacturing File), which store data about the object’s geometry. The better your design, the better your print!

The “Slicing” Magic

Once your 3D model is ready, it needs to be translated into instructions that your 3D printer can understand. This is where “slicing software” comes in. This ingenious program takes your 3D model and virtually slices it into hundreds, sometimes thousands, of ultra-thin horizontal layers. It then generates a set of precise instructions, known as G-code, which tells the 3D printer exactly where to move, how much material to dispense, and at what temperature for each individual layer. It’s like giving your printer a step-by-step recipe for your object.

The Printing Process: Layer by Layer

With the G-code loaded (usually via USB, SD card, or Wi-Fi), the 3D printer springs to life. The printer’s nozzle, print head, or laser system begins depositing or solidifying material onto a build platform, precisely following the G-code instructions for the first layer. Once that layer is complete, the build platform (or the print head) moves slightly, and the next layer is added, fusing with the one below it. This sequential, repetitive process continues until every single layer has been built up, culminating in your complete three-dimensional object.

Bringing it to Perfection (Post-Processing)

While some 3D prints are ready to go straight off the print bed, many benefit from a bit of post-processing to achieve their desired look and feel. This can involve removing support structures (temporary scaffolding built to hold up overhanging parts), sanding down rough surfaces, or even using chemical vapors for a super-smooth finish. For certain materials, processes like annealing can enhance mechanical properties, making the parts stronger and more durable. It’s the final polish that turns a print into a masterpiece.

Exploring the Landscape of 3D Printer Printing Technologies

The world of 3D printer printing isn’t a one-size-fits-all affair. There’s a diverse array of technologies, each with its unique methods, materials, and ideal applications. Understanding these differences is key to choosing the right tool for your project.

Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF)

This is arguably the most common and recognizable form of 3D printer printing, especially in desktop and hobbyist settings. FDM, often referred to as FFF, works by heating a thermoplastic filament (like PLA, ABS, or PETG) until it melts. This molten plastic is then extruded through a nozzle, layer by layer, onto a build platform. As the material cools, it solidifies and fuses with the previous layer. FDM printers are renowned for their affordability and ease of use, making them a popular entry point into the 3D printing world.

Stereolithography (SLA) & Digital Light Processing (DLP)

If you’re looking for high-detail, smooth-surface prints, SLA and DLP are your go-to technologies. These methods use a liquid photopolymer resin stored in a vat. SLA employs a UV laser to selectively cure and solidify the resin, tracing each layer of the object. DLP, a close cousin, uses a digital light projector to flash an entire layer’s image at once, curing it rapidly. Both SLA and DLP are prized for their exceptional resolution and ability to produce intricate parts with fine features, often used for jewelry, dental models, and highly detailed prototypes.

Selective Laser Sintering (SLS) & Direct Metal Laser Sintering (DMLS)

For robust, functional parts, particularly in industrial applications, powder bed fusion technologies like SLS and DMLS shine. SLS uses a powerful laser to fuse tiny particles of polymer powder, layer by layer, into a solid object. The unfused powder acts as a natural support, allowing for complex geometries without additional support structures. DMLS operates on a similar principle but uses metal powders (e.g., stainless steel, titanium alloys) instead of polymers, producing highly dense, strong metal parts suitable for demanding engineering applications.

Other Notable Technologies

The innovation doesn’t stop there! Material Jetting works much like an inkjet paper printer, but deposits droplets of photopolymer that are then cured with UV light, allowing for multi-material and full-color prints. Binder Jetting involves jetting a liquid binding agent onto a powder bed to create parts, often used for sand casting molds or metal parts that require post-sintering. Directed Energy Deposition (DED) is typically used for large-scale metal repair or adding material to existing components, using a robotic arm to deposit and melt powder or wire with a laser or electron beam.

The Transformative Power: Benefits of 3D Printer Printing

The advantages of 3D printer printing extend far beyond mere novelty, offering profound impacts across various sectors.

Unprecedented Design Freedom

One of the most compelling benefits is the ability to create geometries and internal structures that are simply impossible with traditional manufacturing. “3D printing breaks the chains of conventional design,” says Dr. Amelia Chen, Lead Additive Manufacturing Engineer at WMTSV Labs. “It empowers engineers to create intricate lattices for lightweighting, optimize airflow channels, and develop entirely new forms that maximize functionality while minimizing material.” This freedom allows for highly optimized parts, reducing weight and improving performance, especially in demanding industries like aerospace.

Rapid Prototyping and Faster Time-to-Market

Imagine being able to take a concept from a digital sketch to a physical prototype in a matter of hours or days, rather than weeks or months. That’s the reality with 3D printer printing. This rapid prototyping capability dramatically accelerates product development cycles, enabling engineers and designers to quickly test, iterate, and refine designs based on real-world feedback. This speed is a huge competitive advantage, allowing companies to bring innovative products to market much faster.

Cost-Effectiveness and Reduced Waste

While industrial 3D printers can have a significant upfront cost, they often lead to substantial long-term savings. Additive manufacturing inherently reduces material waste by only using what’s necessary to build the part, a stark contrast to the material removal of subtractive methods. Furthermore, it eliminates the need for expensive molds and tooling, which are major cost drivers in traditional manufacturing, especially for low-volume or highly customized production runs. This efficiency translates directly to a healthier bottom line.

Customization and Personalization

From patient-specific medical implants to tailor-made consumer goods, 3D printer printing excels at customization. This technology makes “mass customization” a tangible reality, allowing businesses to cater to individual needs without overhauling their entire production line. This is particularly impactful in fields like healthcare, where custom prosthetics, orthotics, and surgical guides can dramatically improve patient outcomes and quality of life.

Enhanced Supply Chain Efficiency and Localized Production

In a globalized world, supply chains can be complex and vulnerable. 3D printer printing offers a solution by enabling on-demand and on-location production. Businesses can print parts closer to the point of need, reducing inventory storage costs, minimizing transportation expenses, and significantly shortening lead times. This localized manufacturing capability makes supply chains more resilient and responsive to market demands.

3D Printer Printing in Action: Real-World Applications

The impact of 3D printer printing is visible across a remarkable spectrum of industries.

Healthcare and Medical Advancements

The medical field has been profoundly transformed by 3D printer printing. It’s used to create patient-specific surgical models for intricate procedure planning, customized prosthetics and orthotics that perfectly fit individual anatomies, and even implants designed to promote bone growth. The burgeoning field of bioprinting aims to print living tissues and organs, holding incredible promise for the future of transplants and regenerative medicine.

Automotive and Aerospace Innovation

Both the automotive and aerospace sectors leverage 3D printer printing to produce lightweight, complex components that enhance fuel efficiency and performance. Manufacturers print engine parts with optimized internal structures, rapid tooling for production lines, and intricate prototypes. The ability to consolidate multiple parts into a single, complex 3D-printed component reduces assembly time and improves overall reliability.

Consumer Products and Design

From custom footwear with intricate sole designs (think Adidas’s 4D range) to personalized eyewear frames and bespoke jewelry, 3D printer printing brings unparalleled design freedom to consumer goods. Artists and designers use it to create unique sculptures and functional art, pushing the boundaries of creativity and personal expression. Even movie props and intricate costumes now frequently feature 3D-printed elements.

Construction and Education

The construction industry is exploring 3D printer printing to build houses and structural components faster and more efficiently, with some companies already offering commercially available 3D-printed homes. In education, 3D printers are powerful tools, allowing students to materialize their ideas, engage in hands-on learning, and understand complex engineering and design principles in a tangible way.

What are the Challenges and Considerations?

While the promise of 3D printer printing is vast, it’s not without its hurdles. Material limitations, though rapidly expanding, still mean that not all materials are suitable for printing, and some exotic materials can be quite costly. Build size restrictions mean that truly massive objects often need to be printed in segments and assembled, which can impact structural integrity. Furthermore, many parts still require significant post-processing to achieve the desired surface finish or mechanical properties, adding time and labor to the overall production. Finally, the initial investment for high-end industrial 3D printing equipment can be substantial.

The Future of 3D Printer Printing: A Glimpse Ahead

The journey of 3D printer printing is far from over. We’re seeing exciting developments like 4D printing, where objects can change shape or properties over time when exposed to certain stimuli like heat or light. Research into smart materials, multi-material printing, and printing functional electronics directly onto objects continues to push the boundaries of what’s possible. As the technology matures, expect greater speed, more material options, and even wider accessibility, making it an indispensable tool for almost every aspect of our lives.

Frequently Asked Questions (FAQ)

Q: Is 3D printing the same as additive manufacturing?

A: Yes, “3D printing” and “additive manufacturing” are often used synonymously. While “additive manufacturing” is the more formal, industrial term, both refer to the process of creating three-dimensional objects by adding material layer by layer.

Q: What materials can a 3D printer print with?

A: The range of materials is constantly expanding, including various plastics (PLA, ABS, PETG), resins, metal powders (steel, titanium), ceramics, composites, and even certain food items or living cells in bioprinting.

Q: How long does it take to 3D print an object?

A: The time required can vary significantly, from a few minutes for small, simple objects to several days for large, complex, or high-resolution prints. Factors like object size, complexity, layer thickness, and the specific 3D printing technology used all play a role.

Q: Is 3D printing environmentally friendly?

A: 3D printing is generally more sustainable than traditional subtractive manufacturing because it significantly reduces material waste. It also enables localized production, cutting down on transportation emissions. However, the energy consumption of some industrial processes and the recyclability of certain specialized materials are ongoing areas of improvement.

Q: Can anyone use a 3D printer?

A: Absolutely! With the rise of affordable desktop FDM printers and user-friendly software, 3D printer printing is more accessible than ever. Many educational institutions and community spaces even offer access to printers and training for beginners.

Conclusion

3D printer printing is more than just a technological trend; it’s a paradigm shift in how we approach creation and production. From its fundamental additive nature to its diverse technologies and transformative applications across healthcare, automotive, design, and beyond, 3D printer printing empowers unparalleled design freedom, speeds up innovation, and drives cost efficiency. While challenges remain, the future of 3D printer printing promises even greater possibilities. As WMTSV, we’re dedicated to guiding you through this evolving landscape, ensuring you have the knowledge and confidence to harness the power of 3D printer printing safely and effectively. The next big idea is just a print away!